The McMaster Engineering EcoCAR 3 Team Drives the Automotive Industry Forward

by Federico Duperly and Alison Bayzat

EcoCAR 3 is the latest installment in the Advanced Vehicle Technology Competition (AVTC) series, hosted by General Motors and the US Department of Energy, and managed by Argonne National Laboratory. This competition challenges students from 16 schools across North America to transform a 2016 Chevrolet Camaro into a hybrid vehicle, while maintaining its consumer appeal and living up to the “Camaro” legacy.

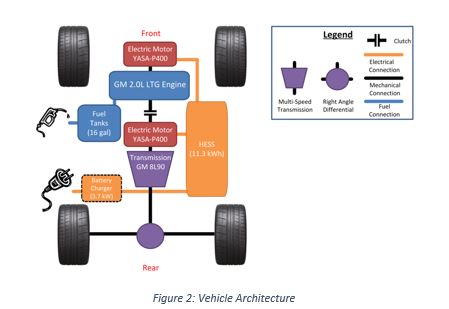

The McMaster Engineering EcoCAR 3 Team strives to create a high-performance hybrid vehicle, nicknamed the “E/28”, with performance characteristics rivalling those of the Z/28 track ready Camaro. The E/28 utilizes an aggressive series-parallel hybrid architecture, with two 90 kW electric motors and a 2.0L 4-cylinder turbocharged engine for propulsion, pushing the total output of the vehicle to over 600 HP and 750 ft-lbs of torque, all while increasing the stock Camaro’s fuel economy to 42 miles per gallon (5.6 L/100km).

One of the most unique aspects of the team’s architecture is the Hybrid Energy Storage System (HESS). The HESS consists of two distinct energy storage systems, which allow the peak power demands of E/28 to be met. The liquid cooled 10.8kWh Lithium Ion battery pack provides the bulk of the energy storage for the vehicle. It is interfaced with the DC bus through a high power bidirectional DC/DC converter. On the DC bus side, an ultra-capacitor pack capable of 120kW of symmetrical charge and discharge power satisfies the peak demands of the electric motors during acceleration and regenerative braking. In total, the 11.3kWh HESS is capable of 180kW of power output with a far superior power to weight ratio than a standard Lithium ion energy storage system. The philosophy behind this architecture is to break the stereotype that hybrid vehicles must sacrifice performance for efficiency and range, and prove that an electrified powertrain can meet and exceed the performance characteristics of a conventional powertrain, while remaining environmentally and consumer friendly.

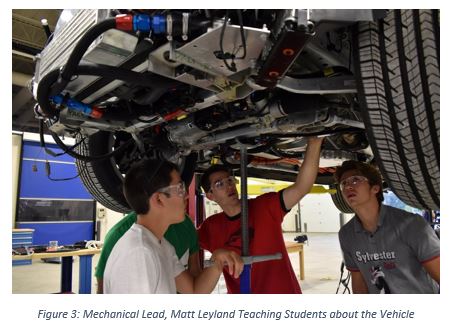

The team is currently comprised of nearly 70 students, with disciplines spanning across engineering (i.e. Mechanical, Electrical, Computer, Software, and Chemical), as well as, Communications and Business. Members range from first year undergraduate students all the way to Masters and Ph.D. students. The team has the support of Dr. Emadi, Dr. Lawford, Dr. Centea, Dr. Habibi and Dr. Veldhuis at McMaster University. Alongside the faculty support, the McMaster Engineering EcoCAR 3 Team has the support of 40+ competition sponsors and 50+ team sponsors.

The team is broken into four engineering sub-teams, Mechanical, Electrical, Innovation and Controls, as well as the Communications sub team. The electrical sub-team has students designing, populating, and programming custom printed circuit boards (PCBs), while also developing custom wiring harnesses for the vehicle. The controls sub-team uses hardware in-the loop, model in-the loop and software in-the loop techniques to develop and integrate a custom control strategy into the vehicle. Students on the mechanical sub-team focus on designing, packaging, validating, manufacturing and integrating custom powertrain components such as mounts and bellhousings. The communications sub-team focuses on consumer appeal to ensure that the vehicle that is being developed is properly marketed to the team’s target audience. Lastly, the innovation sub-team focuses on the development and integration of the HESS into the vehicle.

The opportunity for McMaster University students to be involved with the EcoCAR 3 competition provides them with a unique connection to industry partners, as well as the chance to gain industry specific skills. Students that have been involved with the team throughout their undergraduate or graduate career have currently had a 100% employment success rate after graduating from McMaster University.

Over the first three years of the competition, the McMaster Engineering EcoCAR 3 Team has been extremely successful, achieving the following awards:

Year 1

- MathWorks Modeling Award - 1st Place

- Mechanical Systems Presentation - 1st Place

- Innovation Presentation - 2nd Place

- System Modeling and Simulation Presentation and Demonstration - 3rd Place

- SPACE Embedded Success Award - 3rd Place

- Overall - 6th Place This is the highest Year One placement of any rookie team in the history of AVTC

Year 2

- MathWorks Modeling Award - 1st Place

- AVL DRIVE Award - 1st Place

- General Motors Women in Engineering Rookie Award - Megan Wood

- NSF Innovation Award - 2nd Place

- dSPACE Embedded Success Award - 2nd Place

- Best Winter Workshop Systems Safety Presentation

Year 3

- 2017 Team to Watch Award

- Excellence in Leadership Award - John Reimers

- Siemens PLM Excellence Award – 1st Place

- Innovation Award – 2nd Place

- dSPACE Embedded Success Award 3rd Place

For year 4 of the EcoCAR 3 Competition, the team is focusing on validating and optimizing systems and control logic through vigorous and extensive test plans to ensure the E/28 will be at its peak performance for the upcoming final year competition in May. To learn more about our team and the competition and to follow our progress throughout the year please visit the following:

Website: http://ecocar3.org/mcmaster/about-us/

Facebook: https://www.facebook.com/MacEngEcoCAR3/

Twitter: https://twitter.com/MacEngEcoCAR3

Instagram: https://www.instagram.com/macengecocar3/

Authors Bio:

Federico Duperly is the team’s Engineering Manager and is currently pursuing his undergraduate degree in Mechanical Engineering and Management. This is Federico’s third year with the project, previously acting as a mechanical team member and then the Mechanical Co-Lead.

Alison Bayzat is the team’s Project Manager and is currently pursuing her M.A.Sc. in Software Engineering at McMaster University. Alison has been the team’s Project Manager for Years 2 and 3 of the competition and recently obtained her undergraduate degree in electrical engineering and society with a minor in computer science.

About the Newsletter

Editors-in-Chief

Jin-Woo Ahn

Co-Editor-in-Chief

Sheldon Williamson

Co-Editor-in-Chief

TEC Call for Articles 2023 - Advances in Charging Systems

The TEC eNewsletter is now being indexed by Google Scholar and peer-reviewed articles are being submitted to IEEE Xplore.

To submit an article click here.