Thermal Runway in Lithium-Ion Battery for Mobility Applications

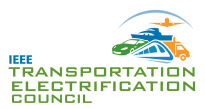

Fig. 1 Causes and effects of Thermal Runaway

Source - Feng, Xuning, et al. "Mitigating thermal runaway of lithium-ion batteries." Joule 4.4 (2020): 743-770.

Effects of thermal issues on TR

Heat in Li-ion batteries occur due to the loose connection of the cell connector. This is usually observed in Hybrid Electric Vehicles (EHV) due to (a) manufacturing defect (b) vehicle vibration. This heat generated spread over wide area causing TR. This phenomenon aggravates when currents of higher C rates are used for charging and discharging. The excessive heat generated travels to the core region of the battery and causes TR. Developing efficient battery thermal models play a vital role in implementing a robust thermal management system. In the recent past, there have been several instances of Li ion battery explosions resulting in property and body damages. In the conventional Li ion batteries containing liquid electrolytes, the separator and the electrolyte are less tolerant to increasing temperature than the electrodes and current collectors. Due to the high temperature inside and / or outside the Li ion battery, the health of the battery degrades in terms of lowered capacity and increased internal resistance.

Surface temperature of the battery is measured by placing thermo couples at appropriate locations. However, the internal or the core temperature of the battery cannot be directly measured. It is found that the internal temperature exceeds the surface temperature by about 6 – 7ºC. Hence, development of a thermal model for the estimation of internal temperature is a must feature in BMS

Causes of TR

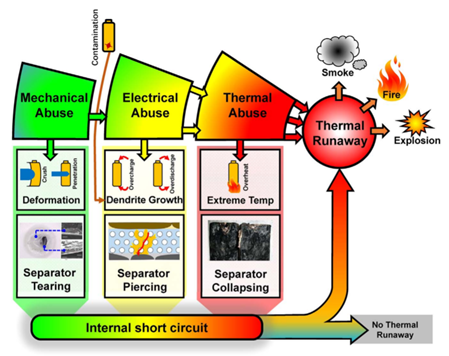

Internal Short Circuit: The most common effect of TR is the internal short circuit (ISC). The short circuit occurs when the anode and the cathode come in contact with each other due to the battery separator failure. The electrochemical energy gets released spontaneously in addition with the heat generation. In general, ISC is triggered due to mechanical, electrical and thermal abuses. A new ISC which is yet to be explored is the Spontaneous ISC which is believed to occur due to the deformities / contamination formed during the manufacturing process. This ISC is a long lasting and complex mechanism to be examined. It is suspected that the failure of Boeing 787 is due to the Spontaneous ISC. Fig. 2 shows the different causes and the effect of TR in Li ion batteries.

External Short Circuit: An external short circuit happens when there is physical deformation of the battery.

Battery Overcharging: In case the battery is overcharged above the maximum voltage specified, for the purpose of range extension of the electric vehicle, would lead to a permanent damage of the battery and reduction in the service life.

High magnitude currents due to rapid charging and discharging of the batteries

Source - https://www.rutronik.com/article/detail/News/lithium-ion-batteries-how-can-thermal-runaway-be-prevented/

Fig. 2 Causes and Effects of TR

Source - Feng, Xuning, et al. "Thermal runaway mechanism of lithium-ion battery for electric vehicles: A review." Energy Storage Materials 10 (2018): 246-267.

Functional Safety and its relationship with thermal runaway of the Lithium-Ion Battery (LiB):

In general, automotive industry follows ISO 26262 standard for functional safety and it contains 12 parts. In part 10, section 12, it provides guidance for system development with safety related availability requirements. In this context, safe state can be achieved by switching off the functionality in case of a malfunction within the system and the safety goal to be achieved. For transportation solutions, failure mode effect analysis (FMEA) and fault tree analysis (FTA) are the common techniques to analyze the faults. FMEA performs the inductive approach and considers the individual faults. FTA performs the deductive approach and considers the combinations of multiple faults. Both FMEA and FTA provide the safety analysis with top-down and bottom-up approach. To avoid thermal runaway the systems cannot be simply switched off, as the safety system should tolerate a fault for a certain period of time. Functional safety standard addresses the detecting faults malfunction faults and communication failures to avoid hazardous events. Based on hazard analysis and risk assessment (HARA),

a) Hazards identification,

b) Hazardous event, and

c) Classification of the identified hazardous event will be done. It leads to appropriate classification of Automotive safety integrated level (ASIL) grade means ASIL A, ASIL B , ASILC and ASIL D. where ASIL D > ASIL C > ASIL B > ASIL A.

The authors declare no conflict of interest. No data / information from Bosch Global Software Technologies (BGSW) were used for this work.

Authors

|

Sumukh Surya is currently working as a Senior Software Engineer in Functional Development Division at Bosch Global Software Technologies Private Limited (BGSW), Bangalore. |

|

Dr. Mohan Krishna. S is currently working as an Associate Professor at Alliance University, Bangalore, India. He was awarded Ph.D. in Electrical Engineering (Sensorless control of induction motor drives for EV applications) from Vellore Institute of Technology (VIT) [Institution of Eminence], India, in March 2017. He received B. Tech and M. Tech degrees in Electrical Engineering from Amrita Vishwa Vidyapeetham [Institution of Eminence], Coimbatore, India in 2009 and 2012 respectively. He also acquired a domain specific MBA (Power Management) from University of Petroleum and Energy Studies (UPES), Dehradun, India, in 2019. His research interests include, electric vehicles, smart homes and IoT-based building energy management systems, state observers for induction motors, energy economics and sustainability etc. |

|

Dr. B. Chandra Sekhar is currently working as Specialist– EV Practice in Transportation Business Division at L & T Technology Services Limited (LTTS), Bangalore. |

About the Newsletter

Editors-in-Chief

Jin-Woo Ahn

Co-Editor-in-Chief

Sheldon Williamson

Co-Editor-in-Chief

TEC Call for Articles 2023 - Advances in Charging Systems

The TEC eNewsletter is now being indexed by Google Scholar and peer-reviewed articles are being submitted to IEEE Xplore.

To submit an article click here.