Trends in Electric Propulsion

By Kaushik Rajashekara, Fellow IEEE, Department of Electrical Engineering, The University of Texas at Dallas, Richardson, TX

Electric vehicles (EV) have been around since late 1800’s. However, in the past, EV development activities were discontinued because of low cost of gasoline and advancement of internal combustion engines. In the last decade, Electric vehicles (EV) and Plug-in Hybrid Electric Vehicles (PHEV) are gaining increasing interest in North America and in other countries due to rising fuel prices, concern for the environment and the sustainability of fossil fuel based transportation.

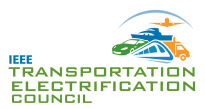

The critical subsystem required in an electric vehicle is the propulsion system, which provides the tractive force to propel the vehicle. This propulsion system consists of an energy storage system, the power converter, the propulsion motor and associated controllers as shown in Figure 1.

In the area of power electronics, presently Insulated Gate Bipolar Transistor (IGBT) devices are being used in almost all commercially available EVs, HEVs, and PHEVs. The IGBTs will continue to be the technology of choice until the silicon carbide (SiC) and gallium nitride (GaN) based devices are commercially available at a cost similar to that of silicon IGBTs. Various properties of silicon carbide such as; wider band gap, larger critical electric field, and higher thermal conductivity enables the SiC devices to operate at higher temperatures and higher voltages offering higher power density and higher current density than the pure Si devices. Gallium devices are projected to have significantly higher performance over silicon-based devices, and much better performance than SiC devices, due to their excellent material properties such as high electron mobility, high breakdown field, and high electron velocity. GaN-based power electronics also feature both low on-resistance and fast switching, leading to substantial reduction in both conduction and switching losses. Achieving the highest power density in a compact package (considering the thermal aspects and reliability) is critical for successful deployment of power electronics systems in electric and hybrid vehicles.

Continuing worldwide R&D by industry, academia, and government will advance the propulsion technologies further, making EVs more viable with longer range, higher performance, and lower cost. All electric vehicles will be joined by PHEVs and PFCVs to serve broader segment of the transportation market. The acceptance these vehicles will be judged based on their performance, reliability, lifespan, and cost.

References

1. “Nissan Leaf Overview”, March 2010.http://www.mwcog.org/uploads/committeedocuments/a15ZXF5X20100316100552.pdf

2. N. Mansfield, “Nissan’s zero emissions future”, Nissan Presentation, December 2010

3. http://www.reuters.com/article/2013/01/24/us-toyota-bmw-fuelcell-idUSBRE90N0L020130124

4. http://www.gizmag.com/ibm-lithium-air-battery/22310/

Dr. Kaushik Rajashekara, Professor of Electrical Engineering and Mechanical Engineering, Distinguished Chair of Engineering. Rajashekara has applied his knowledge of power electronics and technical expertise to create propulsion systems in automobiles, airplanes and industrial applications that run more efficiently, producing fewer emissions and using fewer natural resources. He joined UT Dallas after several years with companies such as Asea Brown Boveri, General Motors Co. and Rolls-Royce Corp. He joined Delphi, then a division of General Motors, in 1989 where he worked on propulsion systems for electric, hybrid and fuel cell vehicles. He was the lead engineer on power electronics for the propulsion system for GM EV1, the first electric vehicle that was commercially available in the United States. He then became chief scientist for propulsion, fuel cell, and advanced energy systems. Rajashekara joined Rolls-Royce as the chief technologist for electric power and control systems.

Dr. Kaushik Rajashekara, Professor of Electrical Engineering and Mechanical Engineering, Distinguished Chair of Engineering. Rajashekara has applied his knowledge of power electronics and technical expertise to create propulsion systems in automobiles, airplanes and industrial applications that run more efficiently, producing fewer emissions and using fewer natural resources. He joined UT Dallas after several years with companies such as Asea Brown Boveri, General Motors Co. and Rolls-Royce Corp. He joined Delphi, then a division of General Motors, in 1989 where he worked on propulsion systems for electric, hybrid and fuel cell vehicles. He was the lead engineer on power electronics for the propulsion system for GM EV1, the first electric vehicle that was commercially available in the United States. He then became chief scientist for propulsion, fuel cell, and advanced energy systems. Rajashekara joined Rolls-Royce as the chief technologist for electric power and control systems.

"Power electronics is the enabling technology for propulsion that can make any system more efficient," he said. "It is the key technology for development of renewable energy-based electric power generation."

Rajashekara has given more than 100 invited presentations in more than 40 countries.

"There was a time when there was not a demand for power electronics professors in the United States," said Rajashekara, who holds more than 30 U.S. patents. "People have awakened to the area of power electronics, and professors at research universities such as UT Dallas are poised to make contributions to society that last for generations."

About the Newsletter

Editors-in-Chief

Jin-Woo Ahn

Co-Editor-in-Chief

Sheldon Williamson

Co-Editor-in-Chief

TEC Call for Articles 2023 - Advances in Charging Systems

The TEC eNewsletter is now being indexed by Google Scholar and peer-reviewed articles are being submitted to IEEE Xplore.

To submit an article click here.