Challenges and Opportunities for GaN in Automotive Applications

by Julian Styles

Gallium nitride (GaN) semiconductors offer the promise of more compact and efficient power electronics, leading to lighter and more energy-efficient vehicles.[i] But where can we expect to see real benefits from GaN in automotive? And what challenges remain to be overcome to make this happen?

State of Technology

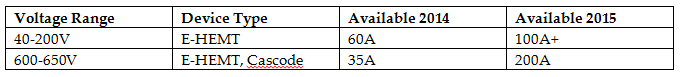

GaN technology has progressed very rapidly in the last 2-3 years, with devices now announced or available that meet the voltage and current requirements needed for automotive applications. The following table describes available and announced products.[ii]

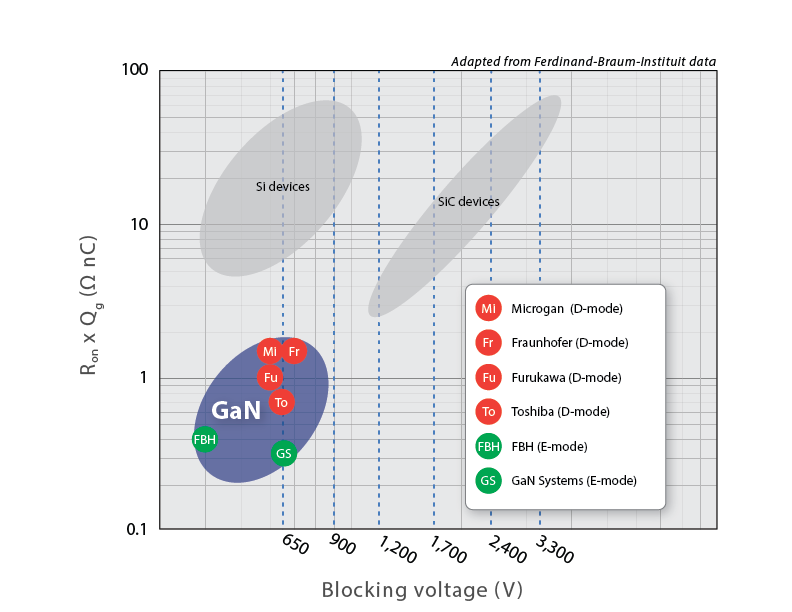

All of these devices have switching performance (switching energy, FOM) between 10 and 100 times better that silicon MOSFETs or IGBTs, and operating temperature ranges of at least -40 to +150C. Figure 1 shows the figure-of-merit vs. blocking voltage for different technologies – this chart also shows why SiC and GaN are increasingly considered as complementary rather than competing technologies. [iii]

Opportunities

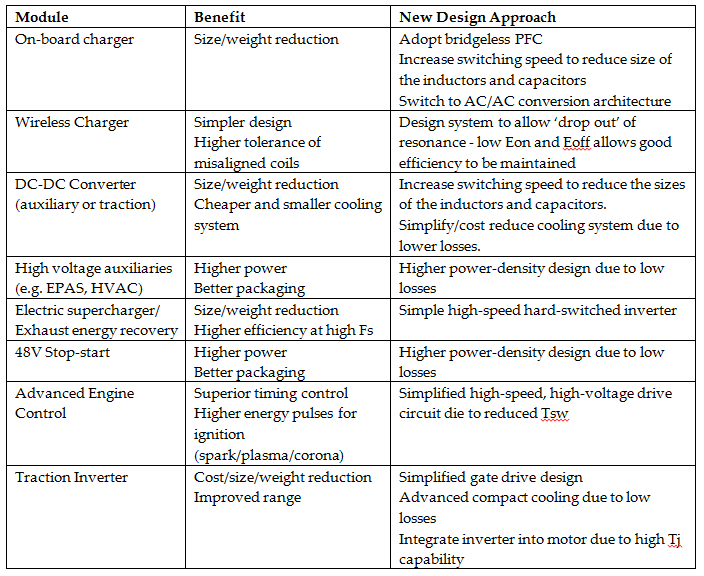

Listed below are some examples of vehicle–related applications that can potentially benefit from GaN. In every case, GaN devices are not ‘drop-in replacements’ for silicon devices in existing designs – instead, they allow new design approaches which deliver significant benefits.[iv] [v] [vi] [vii]

Challenges

There are always practical obstacles to be overcome before any new technology achieves widespread adoption, and GaN is no exception to this.

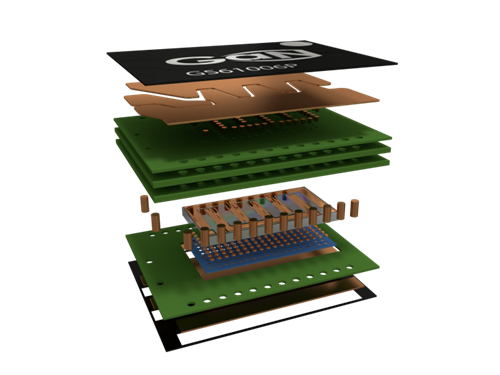

Packaging

GaN devices offer very fast switching and very high power density. To use the devices at their full potential, their packaging must have both very low parasitic inductance and high thermal performance. New packaging approaches – such as embedding dies in packages similar to a multi-layer PCB, see figure 2 – have achieve the required performance at low cost (and without wirebonds, removing a weak link in device reliability). [viii]

Cost

Available GaN devices sell for a premium over similarly-rated silicon devices today. However, independent market forecasters such as Yole Developpments[ix] and IHS[x] predict that they will be comparable in cost with silicon devices by 2018/9. There are good technical reasons for this view, based on the opportunities for cost reduction in the manufacturing process. GaN-on-silicon E-HEMTs are made using GaN/AlGaN epitaxial layers on inexpensive – typically 6” – silicon wafers. The device foundry process is very similar to a low-cost 90s era (0.5 – 1 µm) CMOS process, and has far fewer steps than a current-generation SJ MOSFET process.[xi]

Reliability and prove-out

For GaN devices to gain widespread acceptance in automotive, manufacturers must be satisfied with device reliability, as demonstrated both by qualification test results and real use in the field. There is good progress here, although, as with silicon, reliability models and testing will continue to be refined and expanded. GaN-on-silicon power devices have been in commercial use for about five years, and experience in practical applications has been good. Published qualification and lifetime test data for GaN devices has so far been positive.[xii] [xiii]

Difficulty of driving

Gate drive design is always a concern for electronics designers adopting new devices. Some early GaN devices required special drivers with clamps to prevent gate over-voltage conditions. New-generation E-HEMTs with wide Vg tolerance are now available, and can be driven by many standard MOSFET drivers simply by changing the gate voltage supply.

Technical understanding

Perhaps the largest remaining obstacle to the adoption of GaN is the dissemination of detailed information about its use. The good news here is that the knowledge is beginning to spread, helped greatly by the efforts of organizations like the IEEE.

Conclusion

GaN is a rapidly maturing technology. It allows new design approaches which can benefit many power electronic systems on vehicles. Good progress is being made on overcoming the obstacles to widespread acceptance of the technology. Now is a good time for power electronics engineers to gain a thorough understanding of the technology.

References

[i] E. Persson, “The Impact of GaN FETs on the Future of Energy and Power Conversion”, Darnell’s Power Forum 2013

[ii] Manufacturer websites for device specifications: www.semicon.panasonic.co.jp/en/, www.irf.com, www.epc-co.com, www.transphorm.com, www.gansystems.com

[iii] J. Roberts, “Lateral GaN Transistors – A Replacement for IGBTs in Automotive Applications”, PCIM 2014.

[iv] S. Araujo, “Prospects of GaN devices in automotive electrification”, PCIM 2014

[v] H Bai, “Design of Wireless Charging Systems for Automotive”, IEEE ITEC 2014, Panel Paper

[vi] C. Blake “GaN Technology: What Power Designers Need to Know” PSMA 2013 pp. 330

[vii] H. Nakata, Normally-off 600V GaN power transistor and applications, ECPE Workshop : SiC & GaN User Forum Nuremberg, May 2013

[viii] A Avron, ” GaN Systems: GaNPX packaging process flow”, Scoop – Power Electronics, 2014

[ix] Yole Développement, “PowerGaN Market Report 2014”, June 2014

[x] R. Eden, “Market Forecasts for Silicon Carbide and Gallium Nitride Power Semiconductors”, IMS Research, 2013

[xi] N. Kaminski, “SiC and GaN Devices –WideBand-Gap is not all the Same”, iPOWER² Warwick 2012

[xii] C. Blake, “Long-term Reliability of 600V GaN, Test Results and Conclusions”, Darnell’s Power Forum 2013

[xiii] Y Ma, “EPC GaN Transistor Application Readiness: Phase Five Testing”, Efficient Power Conversion, 2011

Julian Styles has been working with innovative technologies for over 25 years. He helped develop the technology behind digital cellphones, digital audio broadcast, on-board fast charging for EVs, and grid stability management using EV chargers; and his teams were among the first to integrate personal digital devices, heads-up displays, MP3s and proximity sensing into vehicle interiors. He now works for GaN Systems USA, in Ann Arbor, MI, where he is responsible for introducing the company’s advanced gallium nitride power semiconductors to the US market.

Julian Styles has been working with innovative technologies for over 25 years. He helped develop the technology behind digital cellphones, digital audio broadcast, on-board fast charging for EVs, and grid stability management using EV chargers; and his teams were among the first to integrate personal digital devices, heads-up displays, MP3s and proximity sensing into vehicle interiors. He now works for GaN Systems USA, in Ann Arbor, MI, where he is responsible for introducing the company’s advanced gallium nitride power semiconductors to the US market.

About the Newsletter

Editors-in-Chief

Jin-Woo Ahn

Co-Editor-in-Chief

Sheldon Williamson

Co-Editor-in-Chief

TEC Call for Articles 2023 - Advances in Charging Systems

The TEC eNewsletter is now being indexed by Google Scholar and peer-reviewed articles are being submitted to IEEE Xplore.

To submit an article click here.